When and at what intervals should warehouse shelves be checked?

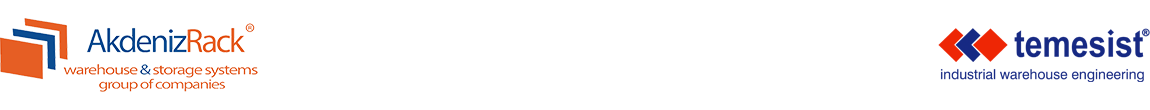

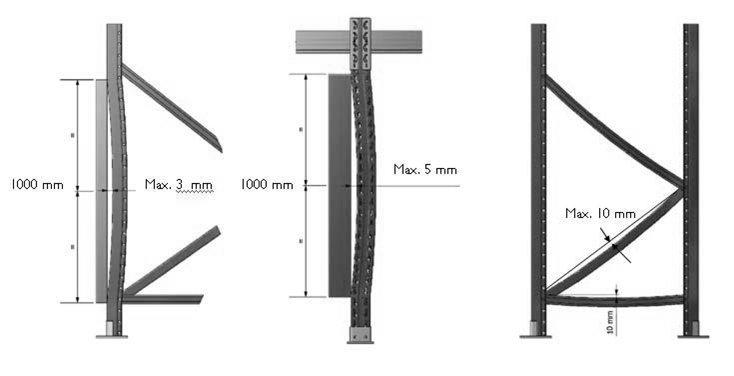

Some warehouse managers roughly check the warehouse; forklift accidents, falling-bending parts or incorrect

Shipments may not report damage immediately. Most common forklift accidents

If there is no collapse as a result of the deformations, it will be ignored and large scales that may arise in the future are ignored.

problems are caused.

It is very important to work with trained personnel who ensure shelf safety in case of damage that may occur during the transportation of materials in the warehouse.

In frequent forklift crashes, first of all, damaged and unstable parts must be identified in order to eliminate the risk of collapse. Certain precautions must be taken to avoid the risk of injury to personnel with continued use of the damaged rack. Sometimes it is necessary to replace damaged parts with new ones.