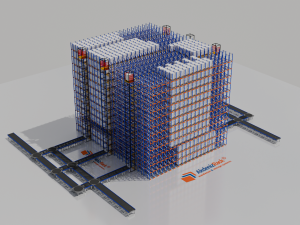

The system named "Multi Layer 4 Way Shuttle System" is a type of automatic storage and transportation system. This system is used for storing, retrieving, and transporting materials in a warehouse or manufacturing facility. It is commonly utilized to meet large-scale storage needs and is frequently found in modern storage and logistics systems with high levels of automation.

This system generally consists of the following components:

Storage Area: Typically created using rack systems or specialized storage units. It represents the area where materials are stored.

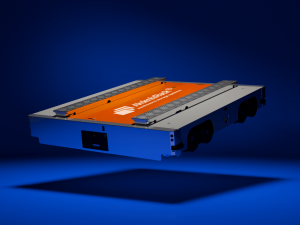

4 Way Shuttle: This is an automatic vehicle used to transport materials within the storage area. It can move in four directions (forward, backward, right, and left) and carries materials in the rack systems within the storage area.

Multi-Layer Structure: This system organizes the storage area into multiple layers, providing increased storage capacity within the same area.

Control System: An automation system managed typically by a computer or centralized control unit. It controls material flow, manages inventory, and monitors system performance.

This system enables effective storage and management of materials within the storage area. Thanks to its automation features, material movement and inventory management are automatically performed without the need for human intervention. This reduces labor costs and increases warehouse efficiency.

This system has many advantages, especially in terms of automation and efficiency:

High Capacity: The Multi Layer 4 Way Shuttle System increases storage capacity and enables more efficient use of available space due to its multi-layered structure.

Automation: Through its automatic operation feature, it minimizes human intervention and automates storage processes, reducing labor costs and error rates.

Quick Access: The multi-layered structure of the system provides quick access to products, shortening order preparation times and increasing customer satisfaction.

Flexibility: The Multi Layer 4 Way Shuttle System can be used flexibly for different types and sizes of products, allowing the storage area to be adapted to various needs.

Reduced Storage Space Requirement: The vertical structure requires less horizontal space, typically resulting in savings in property costs.

Efficiency and Cost Reduction: Factors such as automation, quick access, and more efficient space utilization increase overall efficiency while reducing operating costs.

Sustainability: Factors such as reduced space usage, energy savings, and lower labor requirements provide sustainability advantages.

-300x225h.png)

-300x225h.png)

-300x225h.png)

-300x225h.png)

-300x225h.png)

-300x225h.png)